mould time rock 'n' roll

Tuesday, December 25, 2012 at 7:18PM

Tuesday, December 25, 2012 at 7:18PM

It may not look too different from the last pics I posted, but with the laminate floor installed, I spent the last week or so buying, painting and installing baseboards and quarter-round. This was delayed because I needed an air compressor and nail gun (handyman Keith repo'd his before the floor was finished). To make a long story short, I ended up buying a little three-gallon compressor from the always high-end Harbor Freight. With one of their coupons, it set me back a whopping $39.99, which is insanely cheap (THIS is it, if you're interested). I borrowed a 16 AWG trim nailer from John (which made me wish I had Keith's nicer one- this one sometimes doesn't fire the nails, which is super annoying). Anyhow, doing baseboards and quarter-round isn't hard per se, but it's tedious... zillions of angled cuts with John's compound mitre saw. It's super easy to get confused on which direction the angle of the cuts is supposed to be, so you tend to screw up a lot, which is partially why I wildly underestimated how much baseboard I'd need, so I had to make a second trip to the Depot to buy more.

For reference, pretty the same shot when I moved in. Yuck, it's like a poopy brown cave! Unfortunately, this is exactly how all three bedrooms currently look- someone really loved shit brown.

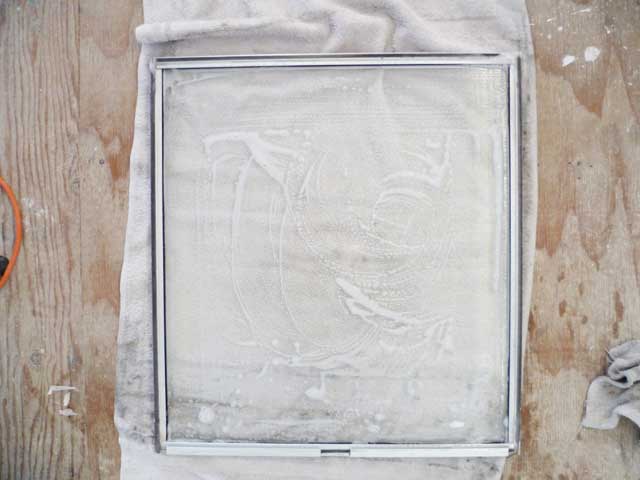

In case you were wondering, those zillions of cuts make a LOT of sawdust (though much of this was from cutting the laminate floor planks):

This is after I picked up the 10,000 little scraps and swept up a considerable amount. I had to towel down the walls too. Only thing left now is the also-tedious task of filling, sanding and paining all the nail holes (I initially painted them all outside prior to installation to avoid the mess and muck of paint you see in most houses).

Some fun details...

Not sure I photographed it that well, but I had to do a tricky indentation into the quarter round to accomodate this vent. I did it with the table saw (not really the ideal tool for the job, but you use what you got), I think it came out pretty good.

Remember me yabbing about vintage-looking brushed nickel Schlage Orbit door knobs? Here's one of the ones I ordered, installed in the newly-painted closet door in the studio. BTW, the piece of trim on the door frame was also tricky because the moulding was too wide to fit, so I had to rip it down with the table saw to make it fit. This would've been easy, but of course the width wasn't consistent. It was the same at the top and the bottom, but the cabs sort of bulged out in the middle, so I marked the moulding on the back, connected the dots with a straight edge and cut it freehand with the table saw (there was a fair amount of that kind of thing with the laminate floor too, it's easier than it sounds). As you can see, it still needs some filling and paint touch-up. Eventually I'll replace the hinges on the cabs with silver ones and paint them the same blue; currently they're just raw wood.

Below is the doorway to the vocal booth room. I haven't re-installed the door yet (weighs a ton and still needs a little work), but I wanted to show the nifty "rubber bump" threshold I got for it. Cutting it down to the correct width with the circular saw was not much fun, and when you're done, you have to sand off all the prickly pieces of excess metal with a rotary tool. Wee.

Next thing for the studio is lighting. As you can see in the top picture, it still has that atrocious ceiling fan with a dangling bulb. I've decided to do recessed lighting (yes, I love me some recessed lighting), so I'm just gonna pillage some of the five-inch cans I had intended to install in the family room (I'll buy more later). There's no attic access up there, so I'm going to play it safe and engage the services of handyman Keith. After that, I'll offically relocate my studio from the wee bedroom it's in now to up there... can't wait.

In unrelated news, AllModern finally got me replacements for my schmance Calligaris barstools. If you recall, there was an ongoing saga with the originals because the screws that held them together didn't fit in the metal inserts. Only took five months to get that worked out! I still have the other pair that are messed up so I have get them to send UPS to pick 'em up, and I'm pretty sure they've charged my credit card twice, but they've been relatively cooperative, and they even gave me an extra 30% off for all the trouble (which in truth was really all the manufacturer's fault, not theirs).