Out with the new, in with the old

Sunday, December 22, 2013 at 9:17PM

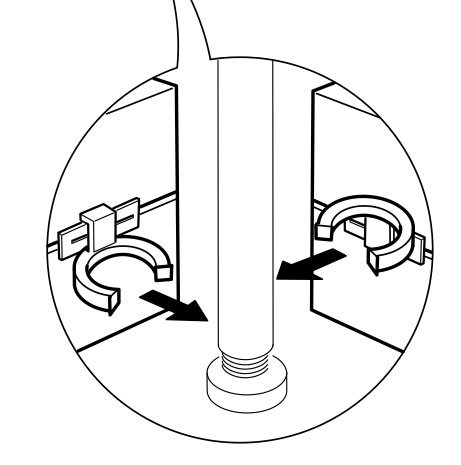

Sunday, December 22, 2013 at 9:17PM For those of you who read my blog, you've seen plenty of pics of my kitchen table. At casual glance it appears to be a classic Eero Saarinen "Tulip" table, but in reality it's a cheapo Ikea Docksta knockoff. I bought it used for next to nothing before I moved to Vegas, and at the time I thought it was a swingin' deal, but two years later I realize it's a bit junky. Unlike a real tulip table, the base is a textured plastic seemingly engineered to collect and retain as much dirt as possible:

Yum, right? You can never get it totally clean because of the rough texture. Additionally, the whole thing isn't really substantial enough, so it's wobble-prone... careful with that coffee, bub.

While perusing the list o' Craig this week, I found what was being sold as a "1950 Knoll Saarinen table, not sure if authentic" for $400. The guy was cool and explained that it was sold to him as authentic, but it didn't have any stickers or indications, so he wasn't sure. It did, however, have a hefty one-piece aluminum base (unlike the Ikea one, which is neither hefty, nor one-piece). I googled how to identify the real deal and came up with two great guides. When I went to look at it, it failed- there's a big wood disc with screws around the perimeter; real ones don't have any visible screws, but the top still screwed into a big rod so the disc part could've been added. In other words, it could be authentic. And it wasn't a 1950- the original was released in 1956. The base clearly had been refinished- not a super great job, but passable- and the top had one little mark, but again, nothing terrible. The guy also had a brand new top with plastic still on it, but movers had chipped the side (probably repairable). Anyhow, $300 later, it was mine, both tops included. And holy crap is that base heavy to move!

(BTW, for reference, a brand new, real one of these tables will set you back a cool $2000 for a 42" like mine. Yikes!)

For comparison, my old Ikea one:

And the new vintage one:

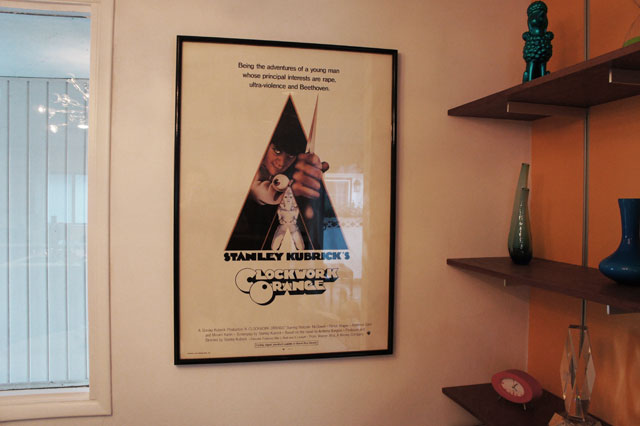

Note the far more elegant curves... the base comes to an almost sharp point at its very bottom and the "stem" is much slimmer. It's hard to see in this pic, but the top tapers gracefully at its edges, whereas the Ikea one has square edges. And the vintage one has a much smoother and shinier top. Now all I need are some matching chairs, like so:

One can get knockoffs for around $200 each, but they're ABS plastic (yuck). The real deals have fiberglass shells with aluminum bases (and $1700 new... each!). I've been watching ebay forever to find a pair, but it's hard to find 'em cheap. The alternative is to get knockoffs by Burke from the 60's or 70's, which are similar and usually a bit cheaper, but they typically have "propeller" bases that I don't like as much.

Here's a gaggle of dorks perched in Burke chairs below from some lame 60's TV show:

... which probably drove their value up.

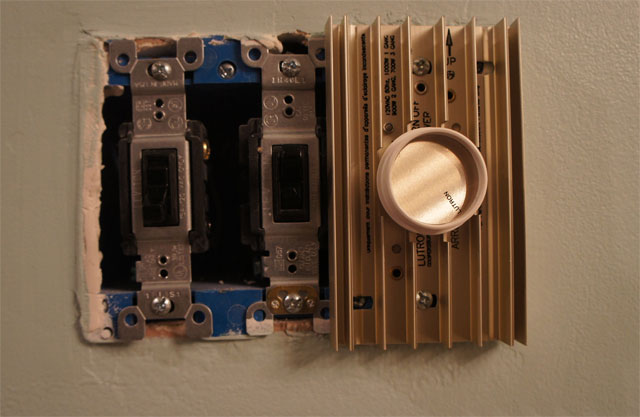

Speaking of 60's spacey crap, Kim recently went on a terrarium mission to fill our kitchen with regional succulents (from the exotic locales of Walmart and Home Depot). We found the nifty 6" tilt bowls online at the also exotic Crate & Barrel. This was her pet project, but my only qualifier was that the plants had to look like stuff that would attack Will Robinson on Lost In Space (see how I sort of contradicted myself there?). Show 'n' tell! (did I mention I love my new camera? Shallow depth of field warms the cockles of my little heart.)

Here's the group photo. And yes, dummy me left the lens cap sitting on the shelf. Doh.